Four Reasons For Choosing Solder Training And Certification

Posted by admin on Jul 19th 2021

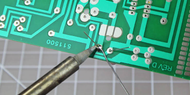

The soldering process used for joining electrical connections on printed circuit boards varies based on the components being soldered and the specific technique used. Hand soldering is a part of the prototype assembly process performed by using hand tools. In this process, a soldering iron is used as the heater as well as flux-containing solder wire. There are many types of soldering techniques used in specific circumstances. Lead-based soldering, lead-free soldering, through-hole soldering, drag soldering, and mini-wave soldering are other popular techniques. The lead-based solder which is most commonly used is typically an alloy of approximately 60% tin and 40% lead.

In soldering and electrical manufacturing, the IPC training and certification enables the engineers to gain an enhanced understanding of the dynamics of the soldering process. Becoming an IPC certified soldering technician expedites the journey of the stakeholders to find jobs and perform quality operations. IPC certification is the standard within the electronics manufacturing industry. You can refer to Illinois Solder Training courses to gain knowledge about the fundamentals of soldering, various soldering techniques, and repair PCBs, BGAs, and other electronic assemblies. With this, it becomes easier to understand the materials, methods, and verification processes involved in the soldering process.

Here are the benefits of obtaining IPC training and solder certification.

Avoid Common Problems in the Soldering Process

Solder training helps the technician to perform high-quality soldering by eliminating the common errors that are likely to arise during the soldering process. Some of the problems that one encounters during hand soldering are solder bridging, excessive solder, solder balling, cold joint, overheated joint, tombstoning, and solder skip. Solder training enables the technicians to learn about good soldering techniques.

Save Time and Costs

IPC certification and solder training will help individuals and businesses to gain recognition as trusted providers in the electronics industry. Since they observe stringent work practices, it helps to bring down production costs, minimize reworking of products, and save time. It helps to costly errors on time. Moreover, it also enables them to practice compliance with the standard regulatory protocols during the soldering process.

Enhance Professional Credibility

IPC training and certification enables individuals and organizations to gain recognition and credibility. The specialized training helps them to remain up-to-date with the current tools and technologies used in the soldering, manufacturing, and PCB assembly process. It boosts professional credibility within your network, clients, and helps to find new business opportunities as it provides them the necessary industry recognition.

Boost Collaboration Efficiency

Solder training helps the technicians improve cross-channel communication and collaboration. It provides them an understanding of the industry standards for the soldering process, as well as training, market research, and public policy advocacy. Adhering to IPC standards helps to produce safe, reliable, and high-performing PCB products. Solder training helps to standardize internal and external communication and ensures that everyone uses the same terminology and agrees on expectations. It also eliminates the errors that arise due to miscommunication.

To Conclude:

Solder training helps to assure the technicians’ commitment to quality. It enables them to bring value to the electronics industry, and perform soldering processes by following the IPC standard to produce quality soldered interconnections and assemblies.